It has long been realised that diversification is inevitable for sustainable growth. Whereas raw sugar is still the main product of the factory, sugar businesses are often selling a range of by-products they have developed depending on the local market demand and the political boundary conditions. For sustainable growth, the sugar manufacturing process needs to be, as a first and foremost step, as energy efficient as possible to be able to benefit further from the diversification opportunities.

BMA’s philosophy of energy efficiency

BMA’s philosophy of energy efficiency

Diversification for sustainability

Modern cane sugar factory – a snapshot

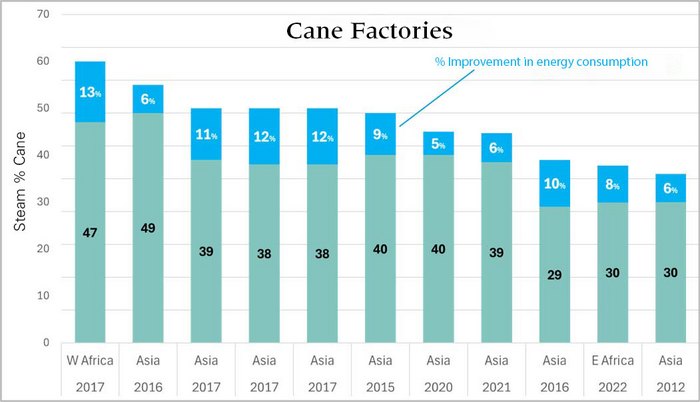

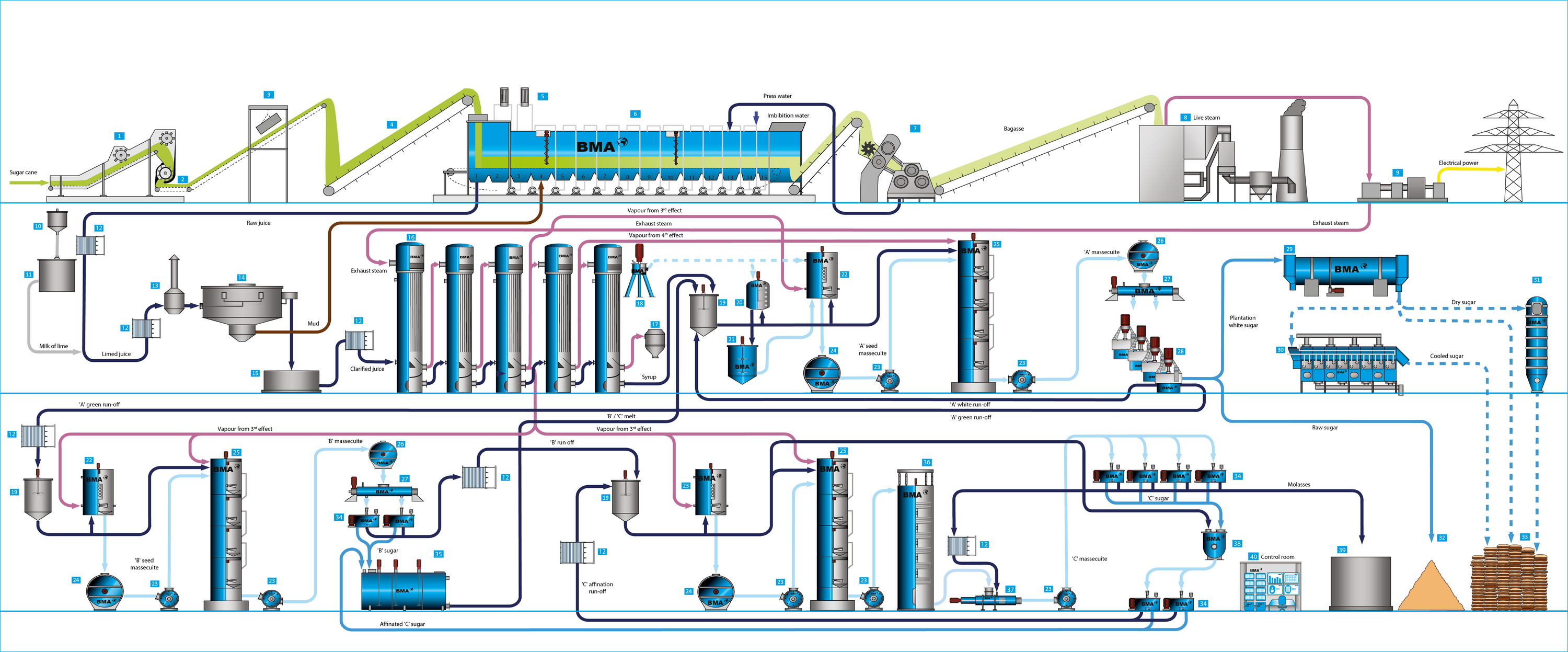

Modern cane sugar factories of today strive to achieve high levels of energy efficiency in terms of steam and electric energy consumption while still focusing on sugar yield and quality. The technologies available today, which are widely accepted, are designed precisely for such factories. The process flow chart shows the complete range of the state-of-the-art equipment from BMA to produce plantation-white sugar and low-colour raw sugar with an estimated steam consumption of 30% on cane and estimated power consumption of 28 kWh/t cane.

Measures and methods

Based on the experience gained by BMA, the measures and methods for achieving a high level of energy efficiency can be summarised in three groups, governed largely by the CAPEX and corresponding energy savings.

Operational improvements

A low CAPEX initiative, the approach focuses on improving working methods and processes, e.g., by supervisor and operator training sessions, administrating standard procedures, etc. to achieve overall energy savings in the range of 5 to 10 % within a period of 1 to 5 years.

Process development

A mid CAPEX proposal, looking to modify the technological setup, such as full seeding, to improve yield and capacity, employing efficient cooling crystallisers to reduce sucrose losses, replacing control valves with variable frequency converters, etc. to achieve overall energy savings in the range of 5 to 20 % within a period of 1 to 3 years.

Process innovation

A high CAPEX project, where major technological changes would be integrated in the factory process. For example, replacing mills with diffusers, providing the evaporator station with additional effects, the use of mechanical vapour recompression to reduce steam consumption. The overall benefit in terms of energy savings could be in the range of 20 to 70% and the project could take up to 3 to 5 years.

Meet us in Florida

BMA’s team will be attending the American Society of Sugar Cane Technologists conference in Charlotte Harbour, Florida from 24 – 26 June 2025. Join us and hear more about modern cane sugar factory concepts and our success stories.