Cooling crystallisers are used in beet and cane sugar factories and sugar refineries worldwide for the crystallisation of sugar from low-purity crystal suspensions (massecuite); they are economical and produce excellent results.

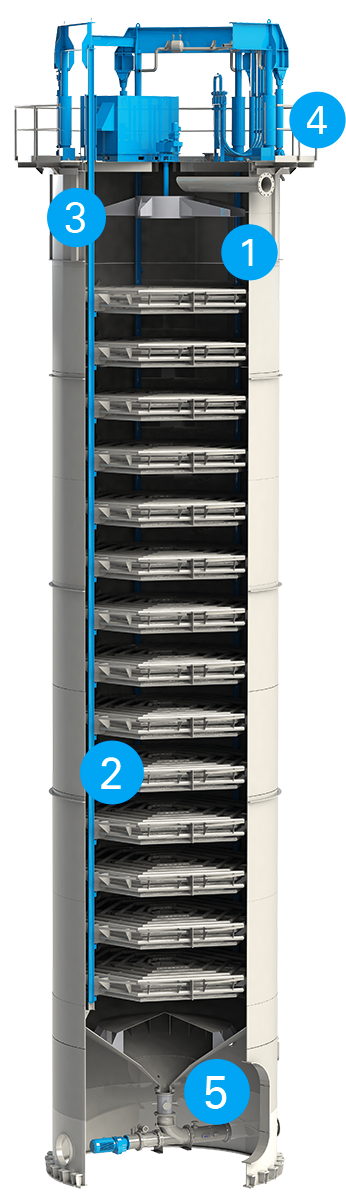

Cooling crystallisers from BMA (OVC) are vertical units consisting of a cylindrical product chamber (1) and cooling pipes (2) only on the inside. Massecuite enters via the product distributor (3). Hydraulic cylinders (4) drive the vertically oscillating cooling packs. The product is discharged at the lower end (5) of the OVC, which can be adapted to fit a specific piping infrastructure.

Design features

- Modularity of OVC cooling blocks and body

- Standard lifting system and standard product distributor

- Compact design

- Easy to integrate with piping systems thanks to standard flanges