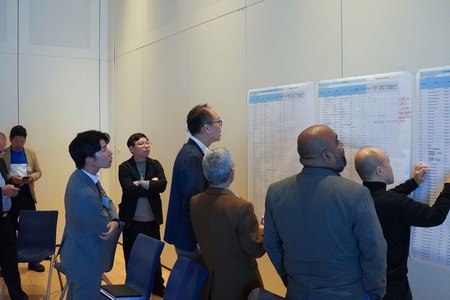

What our customers across the globe value above all is a reliable local contact. Which is why BMA makes sure its agents have in-depth knowledge of the language, market conditions and country-specific features. At the 2025 BMA Agents’ Meeting in early October, around 50 sales partners from many parts of the world came together in Hildesheim to share information about technology developments in the sugar industry and customer requirements in sugar production.

2025 BMA Agents’ Meeting: sales partners strengthen collaboration in the sugar industry

Sharing in-depth knowledge of technology, markets and customer requirements in sugar production within BMA

Global sugar industry: BMA strengthens its network

The four-day meeting aimed to share knowledge about technology developments in the sugar industry and provide even better tailored support to our international customers. Day 1 of the meeting was dedicated to introducing the technology, focusing on the core processes of sugar production – from engineering to extraction and evaporation and to crystallisation.

Our new agents in particular used this opportunity to gain more in-depth knowledge and familiarise themselves with the BMA technologies.

How customer requirements shape the sugar industry

On Day 2, the management addressed BMA’s strategic framework. Head of Sales Oliver Döring focused on markets, projects and BMA’s international sales strategy. CEO Dr. Arend Wittenberg talked about the motivation that drives BMA – and about the company’s expectations of a reliable, value-based partnership with its customers and partners.

Following this, BMA agents reported on developments within the global sugar industry and local market conditions, customer expectations and potential for improvement. This open exchange illustrated clearly how much requirements vary between countries – and how important it is to listen closely.

Technologies from BMA for efficient sugar production

Day 3 centred around customer service and efficiency in the sugar process. Discussions focused on how the plants and machinery from BMA – such as continuous and batch centrifugals, drum dryers or slurry mills – stand up to the challenges of operation, particularly in terms of safety and efficiency.

Another key area was BMA’s service portfolio: a presentation showed, for instance, how our training platform BMA Academy helps customers develop their technical knowledge of the sugar process and operate their plants safely and efficiently.

Sugar production: BMA technology in use at Nordzucker

Rounding off the event was a visit by our sales partners to Nordzucker’s Nordstemmen sugar factory. With the sugar campaign in full swing, they were able to see BMA technology in operation – gaining valuable insights into the sugar process and the practical application of innovative technologies in the sugar industry.

BMA would like to thank the team at Nordzucker for organising the visit and for their hospitality.