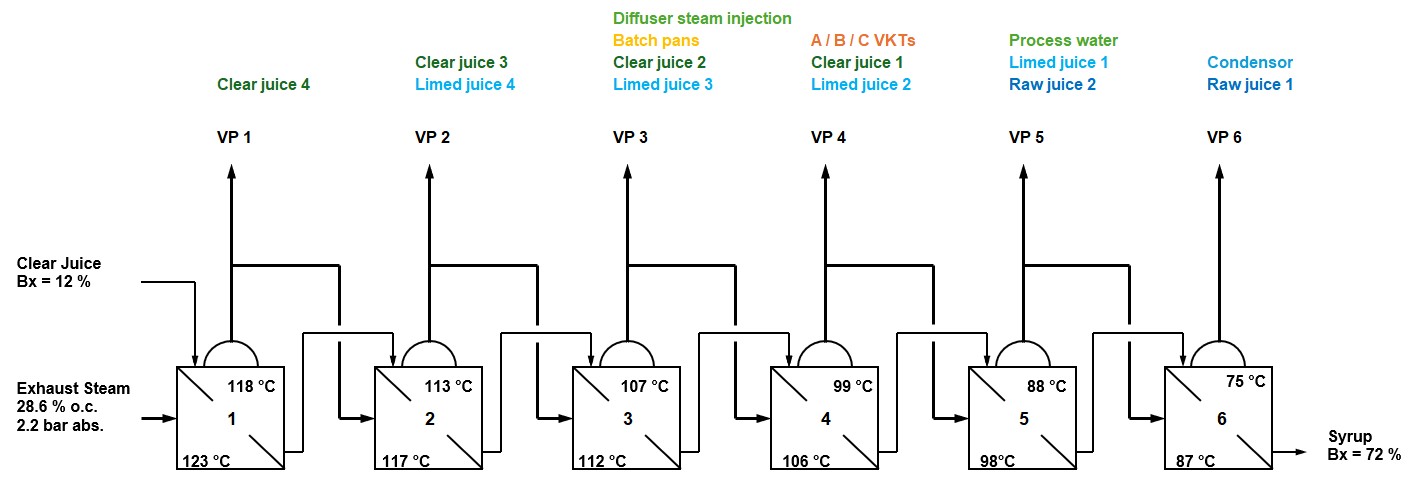

In the sugar manufacturing process, clarified juice is concentrated from ~12 Bx (dry substance content) to ~70 Bx in industrial evaporators configured as multiple-effect systems. The full benefits of energy efficiency measures in the downstream and upstream processes can only be reaped if the evaporation station is perfectly tailored to the complete process.

BMA offers the right evaporator for any application (cane, beet and refinery) and a tailor-made engineering concept to suit your energy efficiency demands.