Der durch ein elektropneumatisches Ventil gesteuerte Magmafluss tritt über das Zuflussrohr in die Zentrifuge ein und kann über den Kompensator überwacht werden.

Kompensator

Ein elektropneumatisches Ventil steuert den Magmazufluss. Der Kompensator dient der Isolierung gegen Vibrationen und Bewegungen im Rohr. Für eine effiziente Magma-Vorbereitung reguliert das doppelwandige Zuflussrohr die Temperatur des Magmas durch Wasser- und Dampfzugabe, letztere über das doppelwandige Zuflussrohr. Der Dampf wirkt sich positiv auf das Fließverhalten des Magmas aus. So wird eine kontinuierliche Produktion ermöglicht und die Masse für die Trennung vorbereitet.

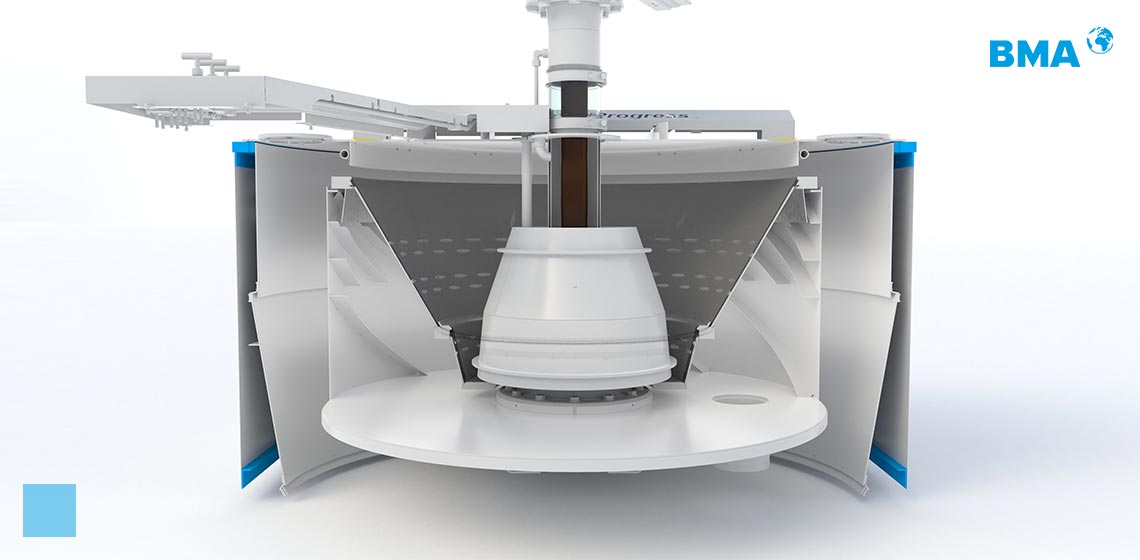

Für hohen Durchsatz und beste Qualität

Eine zügige und dennoch schonende Erwärmung viskoser Füllmassen in unserem gestuften Produktverteiler „Turbo-3“ bewirkt eine exzellente Aufbereitung für die Zentrifugation. Bereits in der Vortrennstufe abgeschiedene Sirupmengen sorgen für höhere Durchsätze gegenüber herkömmlichen konischen Zentrifugentrommeln und damit für mehr Effizienz im Anlagenbetrieb. Mit der gestuften Trommel können Zuckerkristalle von höchster Reinheit und Qualität gewonnen werden. Die patentierten elliptischen Öffnungen im Trommelmantel tragen dazu wesentlich bei.

Danach wird die Füllmasse an der Trommelwand nach oben zum Trommelrand transportiert. Dabei erfolgt die Trennung in Kristalle und Melasse.

Die Melasse bzw. der Sirup wird über die elliptischen Trommelöffnungen in den Melasseraum ausgetragen. Der Abfluss erfolgt über eine bzw. zwei Rohrleitungen, je nachdem ob die Maschine mit einer Siruptrennung ausgestattet ist. Beim Transport der Kristalle nach oben zum Trommelrand wird weiterhin Waschwasser zugegeben.

Kontinuierliche Zentrifugen von BMA für hohe Energieeffizienz

Die kontinuierliche Zentrifuge K3300F ist mit hocheffizienten Motoren, einer gestuften Trommel und dem Turbo3 Produktverteiler ausgestattet und erreicht mit einem wesentlich geringeren Energieverbrauch (bis zu 25 % weniger Strom als die Vorgängerversion K2300) dieselbe Durchsatzleistung. Dank ihres kompakten, materialoptimierten Designs und ihres geringeren Gewichts gegenüber vergleichbaren Zentrifugen anderer Hersteller ist sie in der Fertigung, beim Transport und im Betrieb besonders ressourcenschonend.

![[Translate to Deutsch:] K3300F components: compensator An electropneumatic valve controls the massecuite inflow.](/fileadmin/user_upload/compensator_schauglas_k3300F_continuous_centrifugal.jpg)

![[Translate to Deutsch:] BMA K-serie Product distributor K3300F continuous centrifugal](/fileadmin/user_upload/K3300F_continuous_centrifugal_turbo3_product_distributor_BMA_Kserie.jpg)

![[Translate to Deutsch:] K3300F elliptical openings continuous centrifugal](/fileadmin/user_upload/K3300F_continuous_centrifugal_centrifuge_kontinuierliche_zentrifuge_BMA_Kserie_elliptical_openings_basket.jpg)

![[Translate to Deutsch:] Sugar crystals basket centrifugal K3300F](/fileadmin/user_upload/K3300F_continuous_centrifugal_centrifuge_kontinuierliche_zentrifuge_BMA_sugar_crystals.jpg)

![[Translate to Deutsch:] K3300F_continuous_centrifugal_centrifuge_kontinuierliche_zentrifuge_wet_discharger](/fileadmin/user_upload/K3300F_continuous_centrifugal_centrifuge_kontinuierliche_zentrifuge_wet_discharger.jpg)