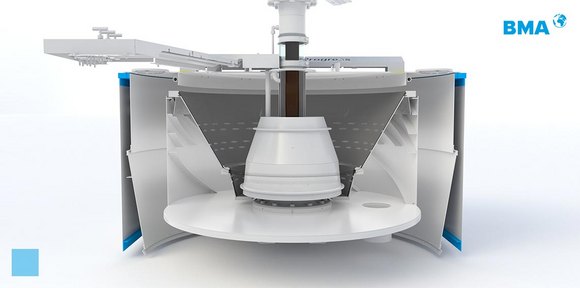

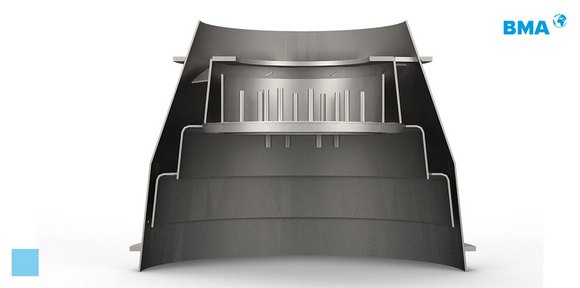

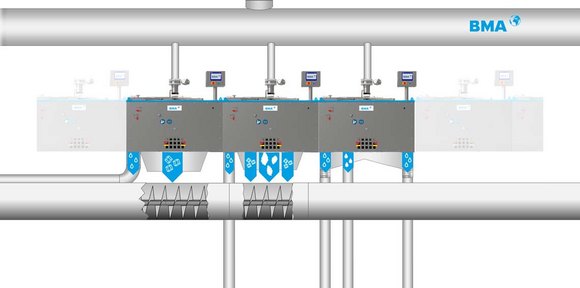

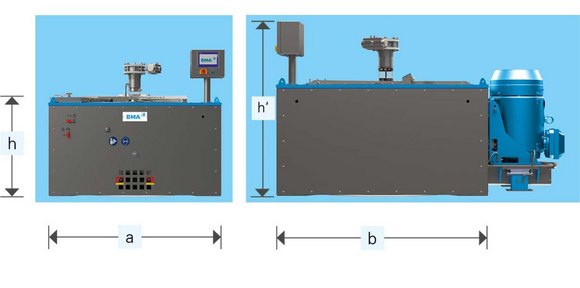

The implementation of continuous processes in production is one factor that ensures efficiency. In sugar production, the continuous centrifugals from BMA ensure continued output coupled with maximum throughput. And even more. Another asset of our centrifugals is their outstanding user-friendliness.