Passion for Progress is the guiding principle for all BMA employees. We collect ideas and gain experiences, make suggestions for improvement, and close gaps in our knowledge. Our motivation is to continuously improve our products.

Faster, higher, stronger

How BMA promotes innovation and achieves better performance

Often, small changes that form part of our continuous improvement process (CIP) enhance a product over time, hardly noticeable for anyone outside BMA. Where larger modifications are required, we go for a complete makeover. Such a “facelift” mainly involves adjustments that concern the design. Process technology innovations, on the other hand, frequently require major changes to the equipment as well. With these new products, we aim to enable advances in our customers’ processes.

At the heart of CIP: our centrifugals

Sure, there is always room for improvement. Minor issues are usually noticed in the day-to-day operation of equipment. Some of them concern better handling, others, changes in the supplies or adjustments in the manufacturing process. But even these small changes need to be reviewed in terms of their cost efficiency. Each modification is rated as part of our CIP. The continuous improvement of series-type production of BMA machinery and equipment such as centrifugals is very common.

A new look and feel for tried and tested technology: the facelift

From time to time, our machinery and equipment need a “complete overhaul”. This so-called facelift also includes innovative ideas that require a change in concept. In a structured approach, we focus on simplifying the design and on standardisation; control and automation technology are also updated. Ultimately, the improvements that form part of a facelift are suitable for presenting a concept more clearly and, wherever necessary, make the options transparent.

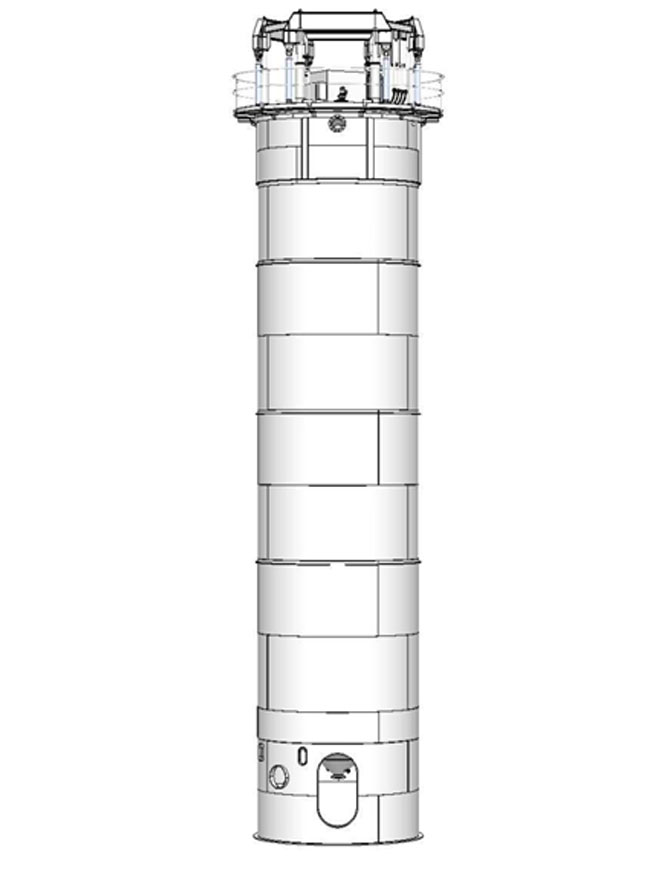

One example of such a facelift is the review of our design for the cooling crystalliser (OVC). The crystallisation of C product is still based on the same established technology and process. And there are no changes to the direction of the process flow in continuous crystallisation: the massecuite still flows through the OVC from top to bottom.

Standardisation of the concept is based on a modular system for the various assemblies such as base, cylinder section, cooling packs and the cover section. Both the hydraulics unit and the control system have been standardised. Overall, the OVC from BMA is now considerably easier to configure, which makes it quicker to compile both the technical and the sales configuration. Thanks to this approach, we have been able to introduce standard processes in production, which shorten our delivery times.

A big step ahead: innovative products

Starting something new, initiating innovation – that is what new products are for. With this goal in mind, we aim to improve process flows, driven in our brainstorming efforts by the Olympic motto faster – higher – stronger. In workshops with employees from a range of disciplines, we look for possible ways of achieving our development goals. The plan for implementation includes actions that are primarily aimed at process technology, automation and design. These are supported by Production and Sales.

At the end of the process is the launch of a new product that is in many ways superior to its predecessor. In the best possible case, this new product itself is an innovation that is well ahead of currently available technology.

Series of massecuite pumps from BMA for a range of new opportunities

Our new series of massecuite pumps incorporates many ideas that, together, have all the characteristics of a new product. We are very much interested to hear how first installations in factories will be received. By improving the processes in our machinery and equipment, we can help improve processes in our customers’ factories. The feedback we collect will then be used in our CIP and in the next facelift, which will mark the start of a new product life cycle.

Innovations

We are open to new ideas and debates that challenge conventions. This is the result:

- State-of-the-art equipment

- Highly efficient machinery and plants

- Optimised processes