Carbohydrates with added value

BMA has been a leading manufacturer of machinery, plants and equipment for the production of sucrose, glucose and fructose for many years, and has unrivalled knowledge of processes and process engineering. We successfully use this knowledge for the crystallisation of a range of sugars and polyol-group products.

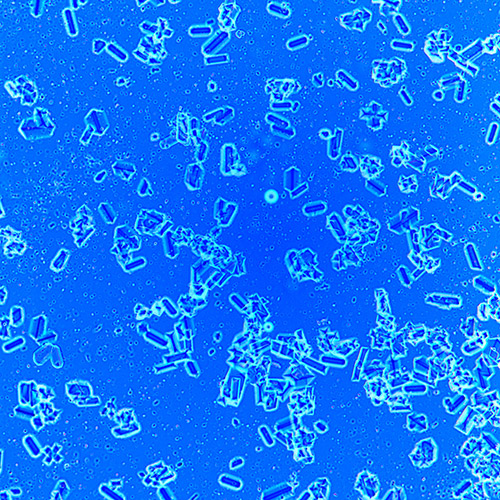

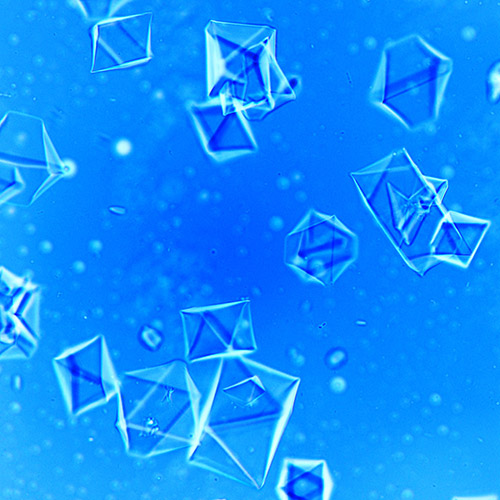

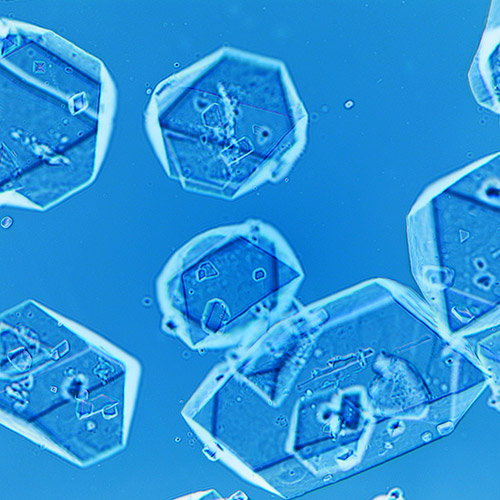

Like sucrose, sugar substitutes belong to the group of carbohydrates. From a legal point of view, they are sweeteners, classified as sugar alcohols (polyols) because of their chemical structure. One of their main characteristics is their sweet taste. Although they are less sweet than sucrose – between 40 and 80 % depending on the product – the taste profiles of some sugar substitutes are very similar to that of table sugar. Demand for crystalline forms of sugar substitutes is growing, and not only for use as sweeteners. Areas of application range from the food sector to pharmaceuticals and cosmetics, and to the chemical industry.