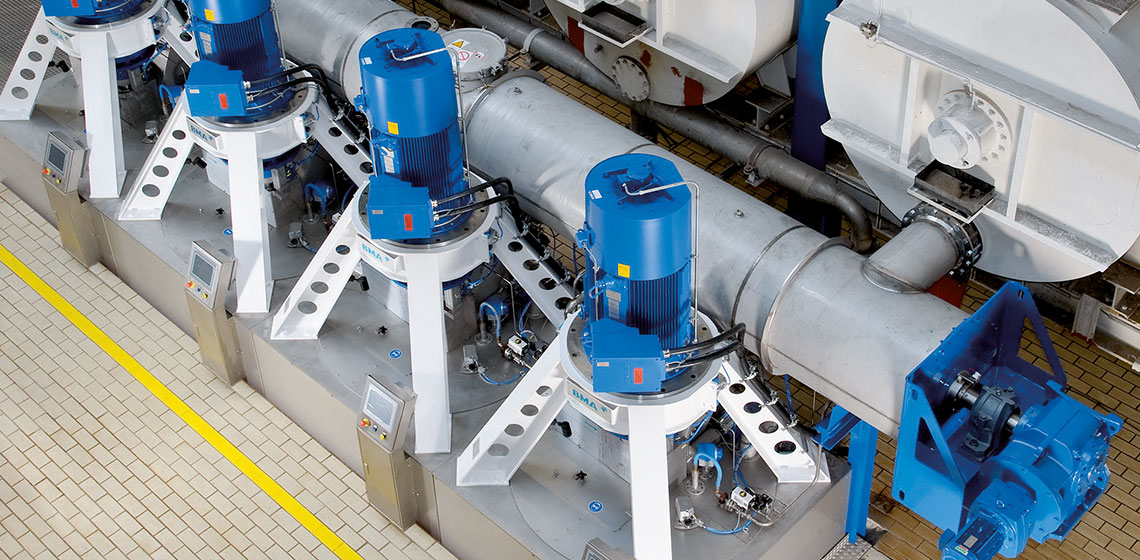

Centrifugals are the most dynamic type of machinery used in sugar production. At high rotational speeds, the sugar crystals are separated from the mother liquor. In the design of our centrifugals, our top priorities are excellent performance, as well as a long service life and outstanding reliability.

Designed to last

With its innovative centrifugal design featuring elliptical discharge openings, BMA has managed to reduce maximum stress acting on the basket shell by more than 40 percent. This increases the calculated lifespan of a centrifugal basket by almost 300 percent.

Modules for tailor-made solutions

Our E series centrifugals come in different sizes and versions. Whether you are producing refined sugar, white or raw sugar, and whatever performance you are aiming for: with our modular system, we will develop a solution that is tailor-made for you.

Safety and quality first

With its outstanding mechanical features, the centrifugal control system from BMA will ensure top performance for your process. BMA centrifugals have such a wide range of settings options that they can be perfectly tailored to your specific production requirements. And with user friendliness in mind, we have developed a user interface that is especially clearly structured and easy to use. Yet another asset is the fail-safe control technology.