High-quality products, short lead times, high efficiency and flexibility – all of these characterise manufacturing today. Plus, of course, on-time delivery.

01.07.2019

The action is here!

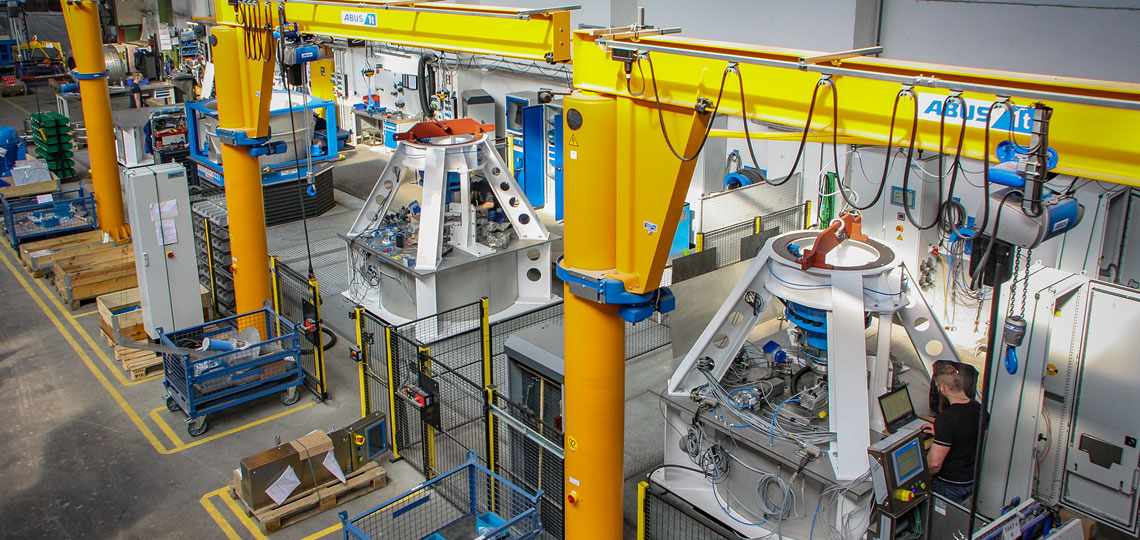

Perfectly divided: cycle time manufacturing at BMA

Meeting delivery deadlines for our centrifugals was one of our top priorities last year. Given that 2017 was a record year for BMA, with orders for more than 250 centrifugals, it was quite a challenge.

Final assembly – four parts make a whole

As reported in last year’s BMA Info, we closely analysed work processes in the final assembly of our centrifugals. Based on the potential improvements we identified, we came up with a new concept for manufacturing: major aspects in the reorganisation were an increase in efficiency, but primarily better ergonomics and greater flexibility.

We decided to optimise not only our internal processes but also the assembly workplaces. September 2018 saw the start of the refurbishment. Just three months later, at the end of November 2018, BMA’s state-of-the-art final assembly line was ready to go, divided into four cycles.

Each cycle comprises specific actions, and one cycle follows on from the previous one. We analysed all former work processes and, wherever necessary, reorganised them. For the reorganisation of actions and for ergonomic workplace design, each task had to be broken down into small steps.

For this task, we relied on methods-time measurement, or MTM, a method for analysing and planning work processes. This breaks down all manual operations into basic motions such as grasp, position or release. The analysis also includes motion elements such as walk/bend or visual check.

For each element, we recorded empirically determined times in tables. The time aspect was of importance to us, as the success of cycle time production depends on the timely start of each cycle.

In the first and second cycles, the basic elements of a centrifugal are assembled and components fitted. The electrical equipment is added in the third cycle. A factory acceptance test (FAT), which marks the end of any assembly process, forms an integral part of the fourth cycle.

Lean production – divide and conquer

A crane moves the centrifugal from cycle to cycle. To account for the differences in size between E-series batch centrifugals and K-series continuous centrifugals, the assembly line is equipped with movable lift tables. Starting with the just-in-time supply of components to the timely handover for shipment, this manufacturing process really has been slimmed down.

We can already report first successes: in 2018, all our centrifugals were shipped on time. One major factor in this was the optimised material flow. Our next step will be to establish cycle time manufacturing in final assembly, which should considerably reduce lead times in centrifugal production.

And we won’t stop there: in 2019, we will be implementing additional modernisation measures – because the introduction of cycle time manufacturing in final assembly is only one element in our forward-looking reorganisation of production. The entire process will be supported by new, state-of-the-art machinery and robots.