Plans for digitalisation and networks in BMA’s workshops

01.07.2017

Teamwork 4.0

For some time now, Industry 4.0 has been the term you hear whenever the conversation turns to the future orientation of mechanical and plant engineering companies. If manufacturers and researchers are to be believed, entirely new and pro table business models can be established with the digitalisation and networking of products.

There are many promising ideas for the use of digital technologies, in almost all sectors of industry. Which is why a fair number of mechanical and plant engineering companies have already geared their product portfolios to Industry 4.0-enabled solutions.

But what about digital transformation of the workshop? BMA has already addressed this issue. At the outset, there was much discussion and debate. In the end, it was clear to all those involved: a planned digitalisation of the workshops is the basis for improved production processes.

Change requires courage

Even greater bene t can be achieved if the development is cleverly linked to the digitalisation of administrative processes. And that will become necessary, as growing customer requirements and increasing international competition are the key issues that drive the Industry 4.0 debate, also in the sugar sector. In times of fast changes and great pressure to adapt, those companies who handle the complex situation best will come out stronger in the end. Plenty of courage will be required, everyone at BMA agrees.

The implementation of our digitalisation scheme will follow a clear plan. A roadmap is needed, to schedule and coordinate all actions; and a platform, to combine the individual steps into a whole. But it will not be possible to automate all processes right from the start. After all, BMA manufactures not only standard products but also large custom tanks in one-off production. Even in future, that will still require parts “hand-made in Germany”.

Shorter searches thanks to digitalisation

BMA has started to put some ideas into action. About two years ago, a tool crib logistics system was implemented at our main workshops in Braunschweig. This adds value by linking the processes tool management, 24 / 7 supply, and tool resource use. It has helped to considerably reduce search times for employees, machine downtimes, and stock levels for tools.

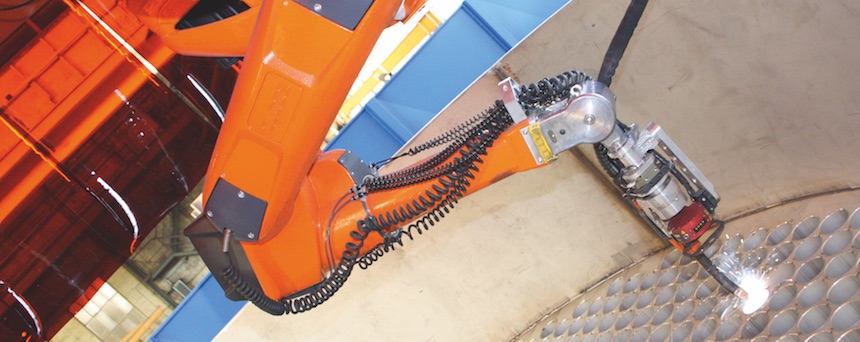

In some places, robots have been deployed. Their introduction required an enormous effort, which could only be accomplished by the whole team. And it has been worth it. Where large quantities of workpieces are required, robots take over the welding, monitored closely by BMA staff.

A typical situation would be when the more than 1,000 tubes have to be welded into the bottom of a calandria. Then the robotic arm moves swiftly from one tube to the next, along one of the ten axes it has available. The quality of the welding seams is impressive, especially considering the high speed. A human welder could not keep up – and he would in fact no longer have the time for this job.

New jobs, new collaboration

Because the skilled worker who used to do the welding is currently developing a computer program for the next biggest calandria, in collaboration with a welding engineer. Both have completed a 3-week crash course at the manufacturer’s. It will take them months to know the robotic system inside out – quite a challenge! Only where the robot can’t reach, the welder himself takes up his tools. How is that for Teamwork 4.0?

We can’t say yet how much of an impact digitalisation will have on manufacturing in the BMA workshops at Braunschweig. Development will pass through several stages in the next few years. What we certainly need are diversity in our construction and manufacturing processes, creativity from our employees – and plenty of enthusiasm for change and courage.