BMA Info 53/2015

A successful year for BMA America

New projects and new colleagues in Colorado.

Breaking new ground in Central America

Last year, a total of four top sugar producers in Central America decided to upgrade their plants. They opted for BMA products – breaking new ground for sugar factories in the region.

Installation and commissioning of a pan seeding system

In the beet sugar industry, pan seeding systems have been established for a long time. BMA has now successfully applied the process in the cane sugar industry.

Manufacturing and service – BMA Brazil expands its capacities

In 2012, BMA set up its subsidiary BMA Brasil Equipamentos Industriais Ltda. – who has since gone from strength to strength. A new production and service centre opened in Indaiatuba in early September 2014.

Interview

BMA Info talks to Igor Djoukwé

A force, to be reckoned with

BMA MENA Industries are going from strength to strength as a design and service provider in the Middle East and North Africa.

Agrosnabsakhar – How a project turned into a big surprise

On first contact with the Agrosnabsakhar sugar factory, nobody at BMA could have foreseen how this collaboration would grow.

Russian pioneers – VKT for a competitive edge

The Russian sugar industry is driving the extension and upgrade of its production sites and BMA plays a key role in this development. The result: a significant increase in output.

Four companies, three continents, two years, one goal

Together with Etihad Food Industries, the BMA Group has got a large-scale project off the ground – collaboration at its best.

Innovations for better performance – A new drying and cooling plant

A good cooling and drying system is the key to high sugar quality. Reason enough for BMA to continuously enhance this equipment, launching new and innovative products on the market.

A premiere in Pakistan – Successful commissioning of two falling-film evaporators

Reducing consumption of resources to a minimum while enhancing performance – those were the objectives for a factory in Pakistan specified in the order JDW Sugar Mills Ltd. placed with BMA.

Indian Cane Power Ltd.– More revenue thanks to co-generation

Indian Cane Power Ltd. (ICPL) relies on bagasse for power generation. For several years now, BMA has helped the company implement its innovative concepts with numerous supplies of equipment.

Uzbekistan‘s most cutting-edge factory

The Angren Shakar refinery was commissioned in August 2014.

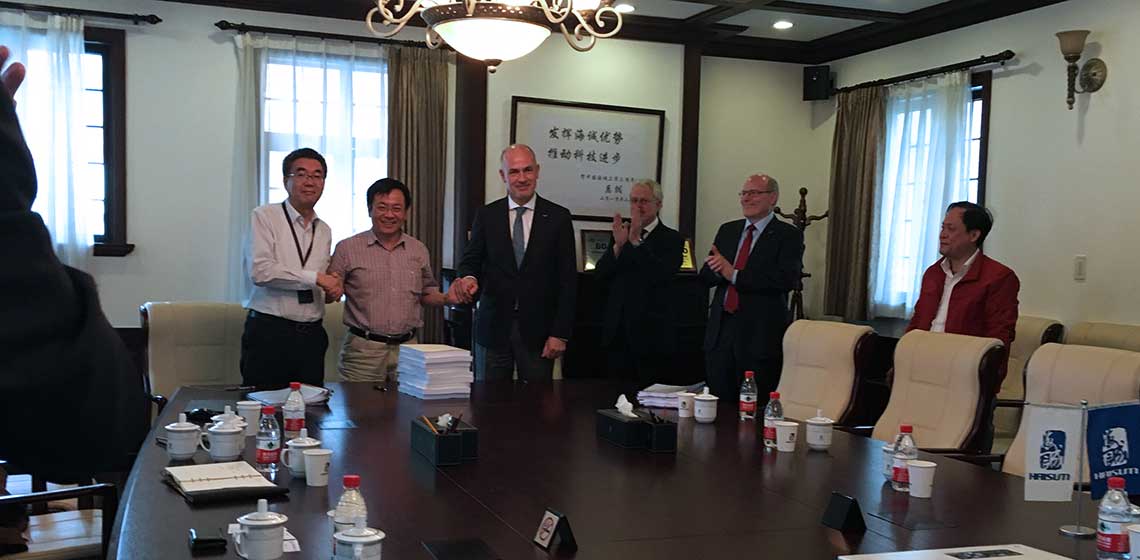

Expanding centrifugal production for China

In 2014, BMA China expanded its assembly range to include not only continuous centrifugals but also batch-type machines (see also BMA Info 52/2014). The model in question belongs to the well-established and reliable B series.

Centrifugals from BMA: Made in Germany

2014 was a truly international year, also for BMA‘s product business: customers on all continents opted for BMA centrifugals.

BMA Automation: a complex factory acceptance test

With the supply of the process control system including all key electrical equipment, BMA Automation was involved in the design of the new refinery in Iraq right from the start. The complex factory acceptance test was a major milestone on the path to the finished plant.

Scientific exchange across the globe – BMA at international conferences

BMA has been presenting the latest developments from current international sugar industry projects at conferences across the globe. The report on the upgrade and capacity extension of the ICPL cane sugar factory is a recent outstanding example.

Engineering projects for the cane and beet sugar industries

In the beet sugar industry, pan seeding systems have been established for a long time. BMA has now successfully applied the process in the cane sugar sector.

Overview of all articles

Dafeng Yinmore Sugar reaches full capacity

China’s population of more than 1.4 billion consumed 16.2 million tonnes of sugar in 2020. The country’s urbanisation has changed the younger generation’s eating habits, including a rapid rise in sugar consumption. For 2030 this is forecast to grow even further to 18.6m tonnes. The new Dafeng Yinmore Sugar refinery built together with BMA plays an important part in meeting this demand.